Extrusions

The term ‘extrusion’ refers to both the manufacturing process and the resulting product, where a heated cylindrical billet of aluminum is forced through a die to create a shaped profile. These extruded sections can be utilized in extended lengths or segmented into smaller pieces for integration into structures, vehicles, or various components. Additionally, extrusions serve as the initial material for processes like drawing rods, cold extrusion, and forging. While the basic operation of most of the numerous extrusions presses globally follows this outline, it’s worth mentioning that some are designed to handle rectangular billets to produce wider sectional profiles. Moreover, certain presses employ an alternative method where the die moves into the billet, known as “indirect” extrusion.

Extrusion Process

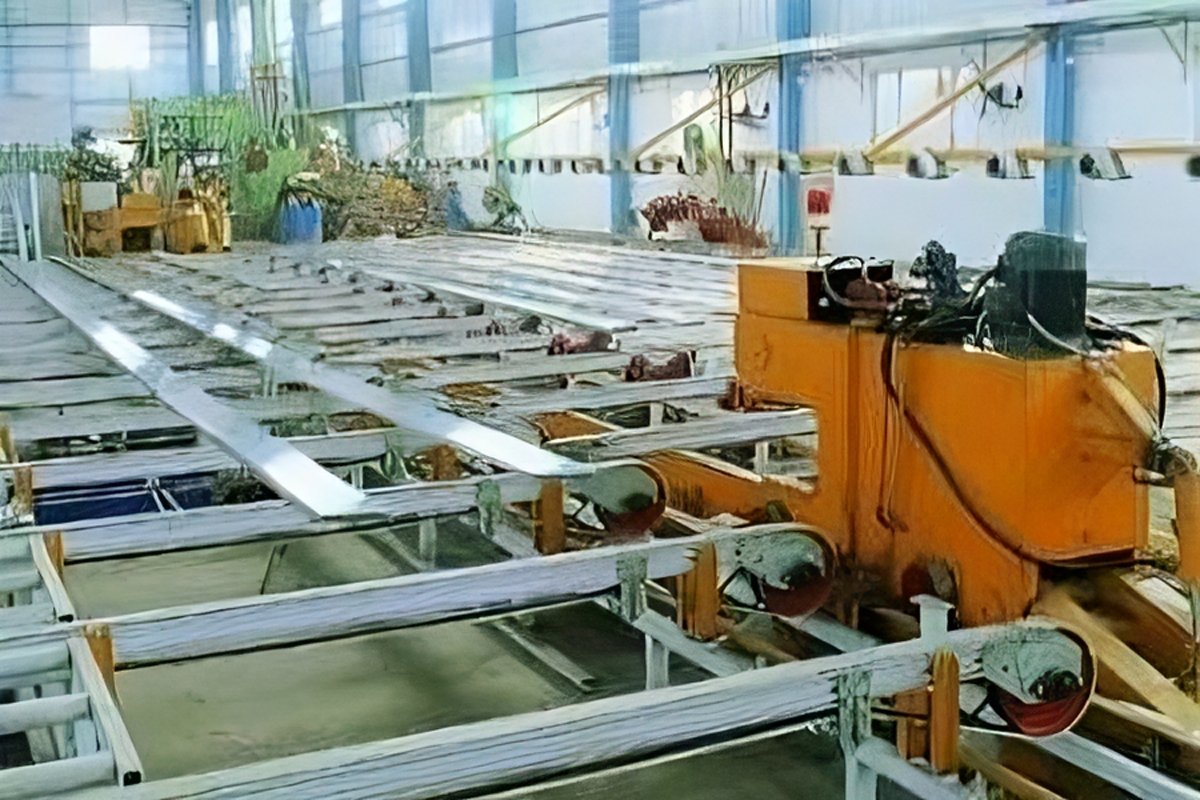

Our modern Extrusion press is based on continuous heating process for homogenous extrusion. The logs are fed into Hot Log Shear where they are continuously heated to desired temperature and cut in to billets as required. The billets are placed in a container (a heated chamber), in which billets are pushed under hydraulic pressure through Ram by the stem, this force squeezes the Aluminium alloy material forcing it to pass through a shaped Die made of Die Steel (special steel alloy).

Extrusion Process

- 1850 MT with 7” Container

- 950 MT with 5” Container

- Single Billet Heater with Hot Log Shear

- 2 Chamber Die Heater, with linear controlled Pullers

- Belt Conveyer Extrusion Handling systems

- Extrusion Quench System

- Undercut Saw for Final Cut

- Ageing Furnace

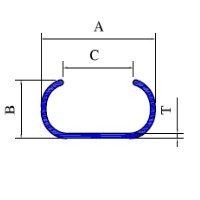

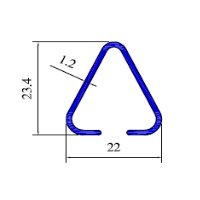

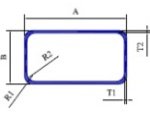

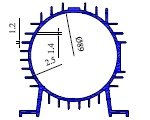

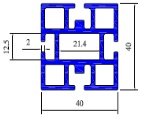

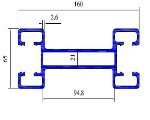

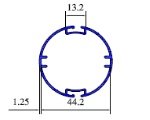

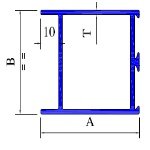

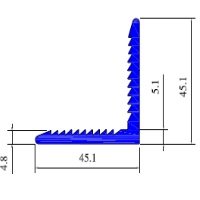

Extrusion Profile Specification

- Extrusion Circumscribing Circle Diameter Solid profile: 145 mm / Hollow profile: 130 mm

- Cross Sectional Area for 6063 Alloy: 2300mm ²

- Cross Sectional Area for 6082 Alloy: 1500 mm ²

- Extrusion Cut Length Offered: 1500mm to 8000mm

- Note: Cut lengths smaller than 1500mm will be considered on special request.

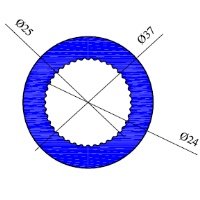

Billet Casting Equipment

SSAIL is equipped with a large scale 8 MT (metric ton) capacity melting furnace, with an ability to perform 4 charges in a 24hr period. Catering to our multiple billet diameter requirements, we have a net capacity of 20 billets per charge for 7” diameter and 40 logs per charge for 5” diameter

SSAIL uses Regenerative Melting Furnace using Hot Top Casting with inset Graphite Ring. SSAIL uses virgin Aluminum ingots purchased from selective primary metal producers and in-house generated scrap while manufacturing Aluminium alloy billets.

SSAIL ensures that standard billet casting procedures are followed in furnace operations, pertaining to grain-refining, using ceramic foam filters, flow controls are made through hydraulic table. During billet casting strict quality measures are taken, samples are constantly monitored for alloy composition using automated spectrometers. Each batch is numbered based on the ISO quality and tracking documentation.

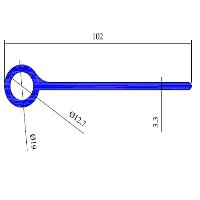

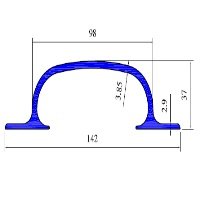

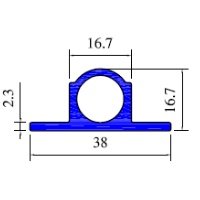

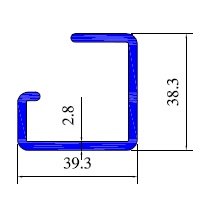

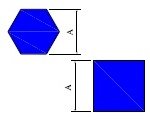

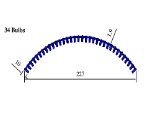

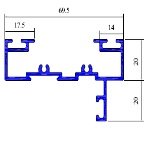

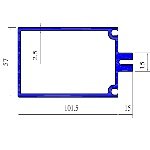

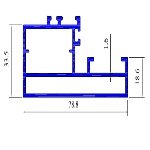

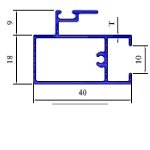

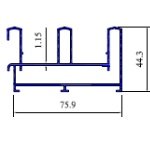

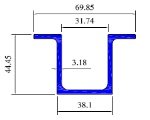

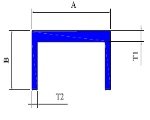

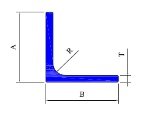

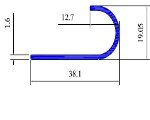

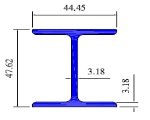

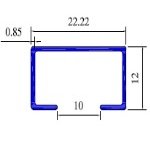

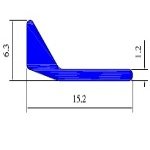

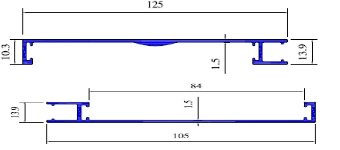

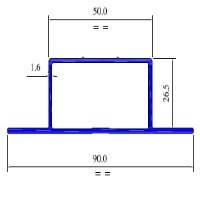

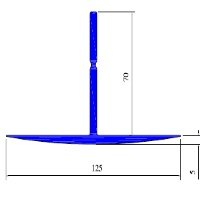

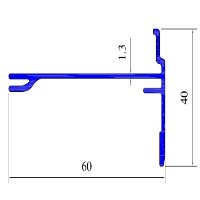

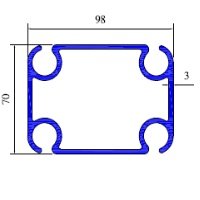

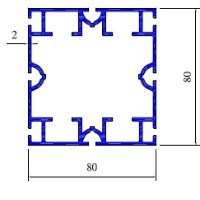

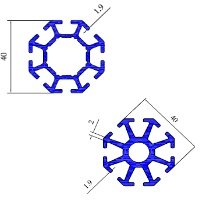

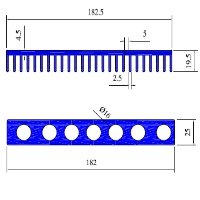

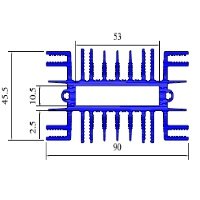

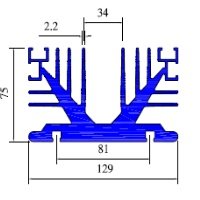

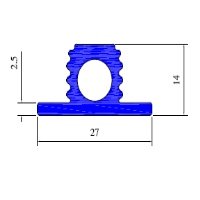

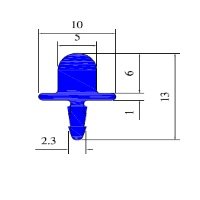

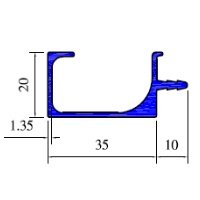

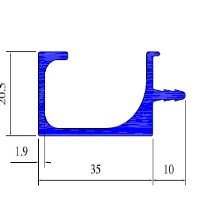

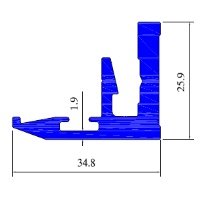

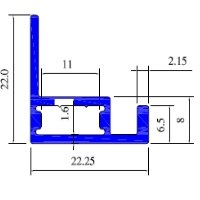

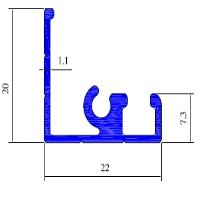

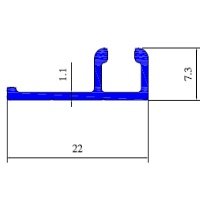

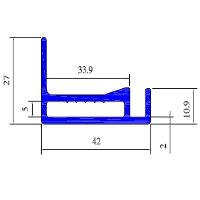

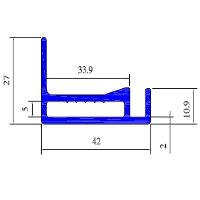

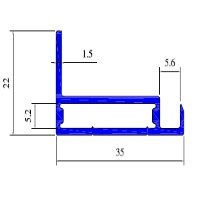

Standard Profiles

SSAIL has a vast collection of dies, over 1800 plus. By virtue of the vast collection we cater to a multiple standard profile options. Standard profiles are commonly used profiles that can be readily manufactured without any lead-time for design / die development/ sample production.

If customer requirements can be met with our standard die collections (Dies available in our extrusion catalog), order placement and processing can be executed with a minimum turn-around time.

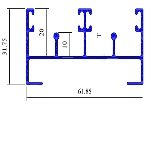

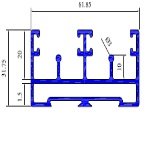

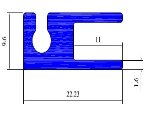

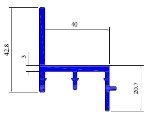

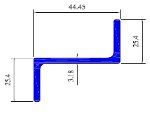

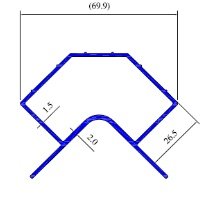

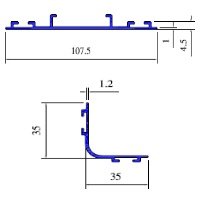

Custom Profiles

SSAIL offers custom designed profile options. Customers work with our design department in preliminary drawings and subsequent design modifications. Our design team offers suggestions based on past experience and in material / weight optimization without loss of functionality.

Custom Die Development Process

Custom Die Development Process involves the following steps

- Customer places quotation request along with the custom design of the profile and related components.

- Customer works with Design team in finalizing drawings and accepts quotation (along with a die deposit)

- Approved Drawings are sent to the In-house Die Development Department

- Sample Extrusions are generated and verified for compliance by the quality team, and sent for Customer Sample Approval.

- Actual quantity order are placed and executed and finalized material shipped to customer.

- Based on customer request custom dies that are proprietary go through a non-disclosure agreement and are not displayed in the Extrusion Catalog.

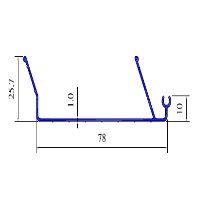

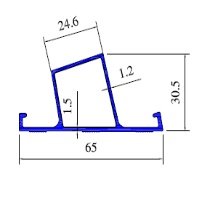

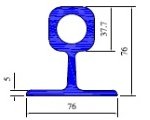

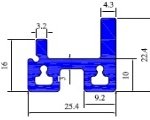

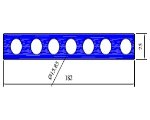

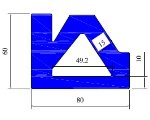

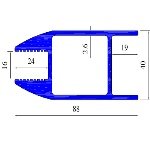

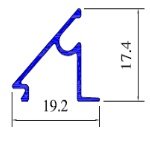

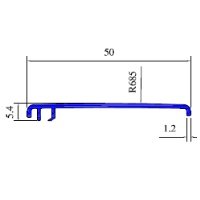

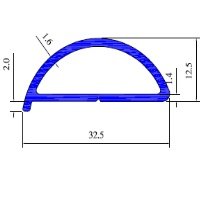

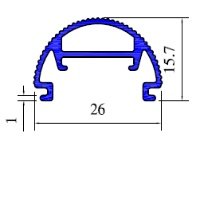

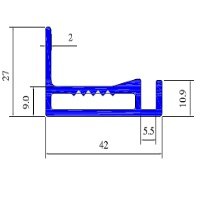

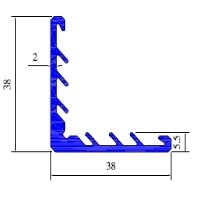

Below are some sample Custom Dies that are developed for different customers in various market segments like Display Boards, Form Works, Venetian Blinds, Industrial, Solar, Modular Kitchen, & Architectural Profiles. These samples are not part of non-disclosure agreement.

Profiles By Industry

SSAIL has its presence in almost all market sectors that consume Aluminum extrusions. SSAIL is a preferred vendor for many customers in multiple market segment as it serves as a single procurement source for raw mill-finish profiles, surface coated profiles, machined components ready for assembly.

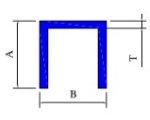

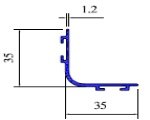

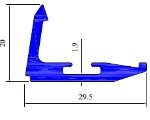

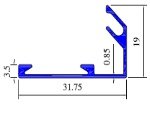

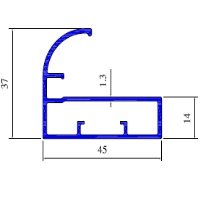

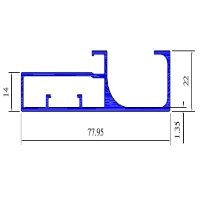

Window Profiles Profiles constitute a major share within this segment. Find below some of the standard window profiles SSAIL has readily available profiles for your needs.

Automotive

SSAIL understands the strength and alloy requirements of Automotive Industry. SSAIL is a preferred vendor for APSTRC, and is a registered vendor for Mahindra and Mahindra and other key automobile manufacturers in south India. SSAIL supports customer requirement with standard profiles and is capable to custom design profiles as per customer requirement through dedicated in-house design team.

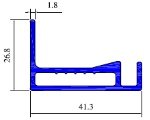

Air-Conditioning Systems

Aluminum is recognized as an attractive construction material for Refrigeration and Air-conditioning Systems. Learnt from Automotive Industry the use of Aluminum Brazed Heat Exchangers is on the rise. Although Copper and Aluminium are preferred metals for making the Tube and Brazed Heat Exchangers for stationary Refrigeration Systems, the use of Aluminium in on the rise due to following reasons

- Price differential

- Lower material costs and weight,

- Better resistance against environmental influences and

- Minimized recycling problems

SSAIL realizes the impact Aluminum Profiles have on the Air-Conditioning Systems and has developed many standard profiles to meet customer demands

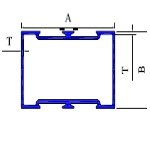

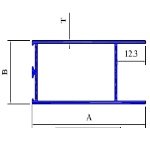

Cleanroom Systems

SSAIL has the previlege of supplying profiles to Cleanroom Systems for its very inception.

Display Boards

SSAIL has a wide collection of Display Board Profiles

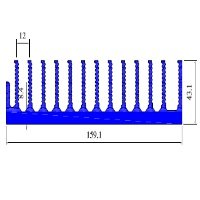

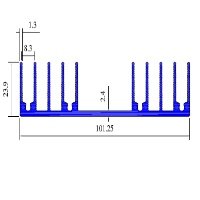

Electrical (Heat Sinks)

Aluminium profiles are widely used for heat sink and other electrical applications. Aluminium alloys 6060 and 6063 are commonly used, with thermal conductivity values of 166 and 201 W/mK respectively. SSAIL provides you the right alloy for your specific electrical application needs.

Interior Design

SSAIL has a large collection of Interior Design profiles. SSAIL quality extrusions combined with Surface Finishing gives customers a single stop shop for all profiles requirements.

Solar Systems

SSAIL takes pride in being one of the largest suppliers of the solar profiles across the Indian subcontinent. Our quality consciousness, alloy combination and ability to provide ready to assemble components for the solar module and racking system manufacturers makes us the premier choice of the Solar industry.

Additionally the Solar module manufacturers and installer both benefit from our two decade plus expertise in the fabrication industry, manufacturing optimization and efficient array assembly of the modules on site.

Consumer Durables

Aluminium extrusion is part of our day to day life and is seen in numerous Consumer Durables. SSAIL has a wide collection of profiles serving different segments within the Consumer Durable component market. These include but not limited to Tower Bolts, Hardware, Door Handles and Ladders.